-

About

-

Our Brand

-

Products

-

Community

Community

Blog

Blog

What is Stainless Steel?

- Writer

- STEELTOPIA

- Date

- 23-09-01

Stainless steel is one of the most recent groups of engineering materials. Although it was invented in the early 20th century, it took decades to become widely used.

It was only after World War II that modern stainless steel was developed and started to be commonly used. The most important characteristic of stainless steel is its corrosion resistance.

Corrosion resistance, combined with excellent mechanical and manufacturing properties, has helped establish stainless steel as an extremely versatile material that, in many cases, provides designers with the only economically feasible alternative.

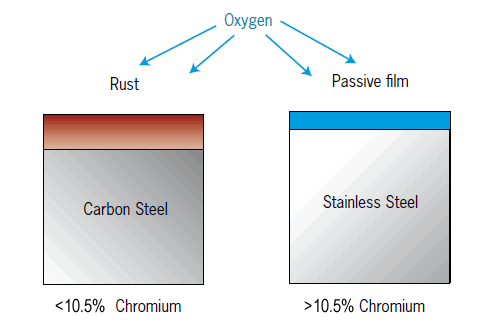

Stainless steel is an alloy of iron (Fe) and chromium (Cr) with the amount of carbon (C) controlled. These are a family of steels containing at least 11% chromium, and their main property is corrosion resistance.

Adding 11% more chromium creates a protective layer. The higher the chromium content, the stronger the passivation film.

Other elements such as molybdenum (Mo) and nitrogen (N) further strengthen the passivation film and improve corrosion resistance. If the passivation film is removed or damaged, it spontaneously reforms in the presence of air or water.

Nickel also makes stainless steel austenitic, and austenitic grades have excellent properties such as weldability, formability, and toughness.

Classification and Grades of Stainless Steel

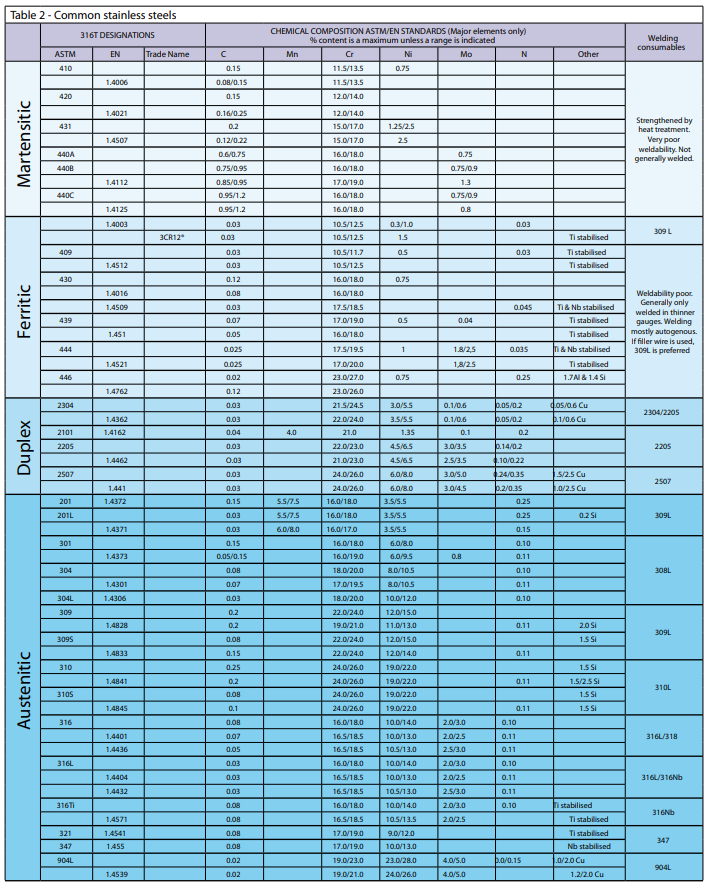

After its invention and initial development, the number of stainless steel grades has increased dramatically, and hundreds of diverse chemical compositions have been standardized worldwide.

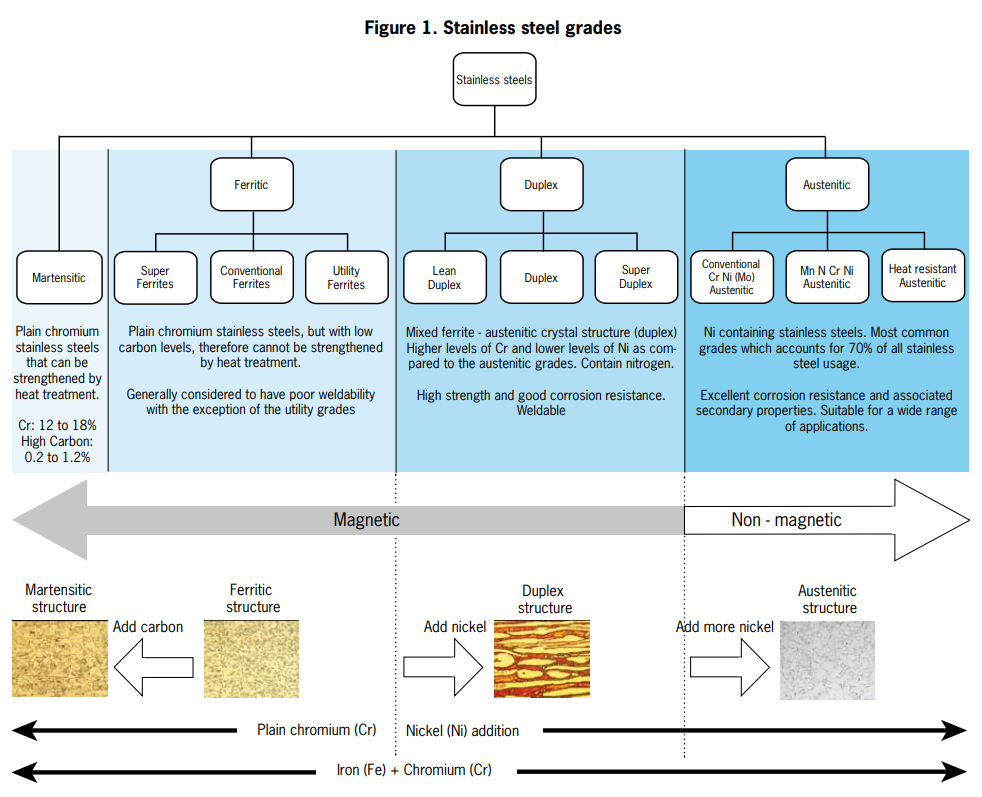

Since the microstructure of steel determines its properties, stainless steel has traditionally been categorized into groups based on its structure. This provides a rough classification in terms of composition and properties.

The relationships between various classifications of stainless steel are summarized below and illustrated diagrammatically.

Martensitic: Martensitic stainless steel is a common chromium alloy with a relatively high carbon content, belonging to the AISI (American Iron and Steel Institute) 400 series. This steel has suitable corrosion resistance, high strength, and hardness developed through heat treatment. It has poor weldability and is magnetic.

Ferritic: Ferritic stainless steel is a chromium alloy with low carbon content and is also included in the AISI series. This steel exhibits excellent corrosion resistance depending on its chromium content. It does not harden or strengthen and has poor weldability, except for thin gauges. It is magnetic.

Austenitic: This steel is included in both AISI 300 and AISI 200 series and has low carbon or low nickel content. It offers excellent corrosion resistance and high-temperature oxidation resistance. Strength and hardness can be increased through cold working. It exhibits excellent cryogenic properties and is non-magnetic. In the 200 series steel, nickel is partially replaced by manganese. These variants share characteristics similar to the 300 series but with higher strength and lower corrosion resistance.

Duplex: Duplex stainless steel has lower nickel content and very low carbon content compared to austenitic alloys. It possesses a dual (mixed) crystal structure of ferrite and austenite. This steel exhibits outstanding corrosion resistance, especially against pitting, crevice corrosion, and stress corrosion cracking. It also has high strength, excellent weldability, and is magnetic.

Corrosion Resistance

The corrosion resistance of stainless steel increases as the chromium content increases and with the addition of molybdenum and nitrogen. The relative corrosion performance of selected stainless steel under atmospheric conditions is listed below.

HOME

HOME