-

About

-

Our Brand

-

Products

-

Community

Community

Blog

Blog

Differences between Drawing and Extrusion

- Writer

- STEELTOPIA

- Date

- 23-10-06

In the manufacturing of seamless pipes, there are two methods that can be used: extrusion and drawing. Each of these processes has its advantages and disadvantages, so it is essential to understand them well and apply the most suitable method to the project.

What is Drawing Process?

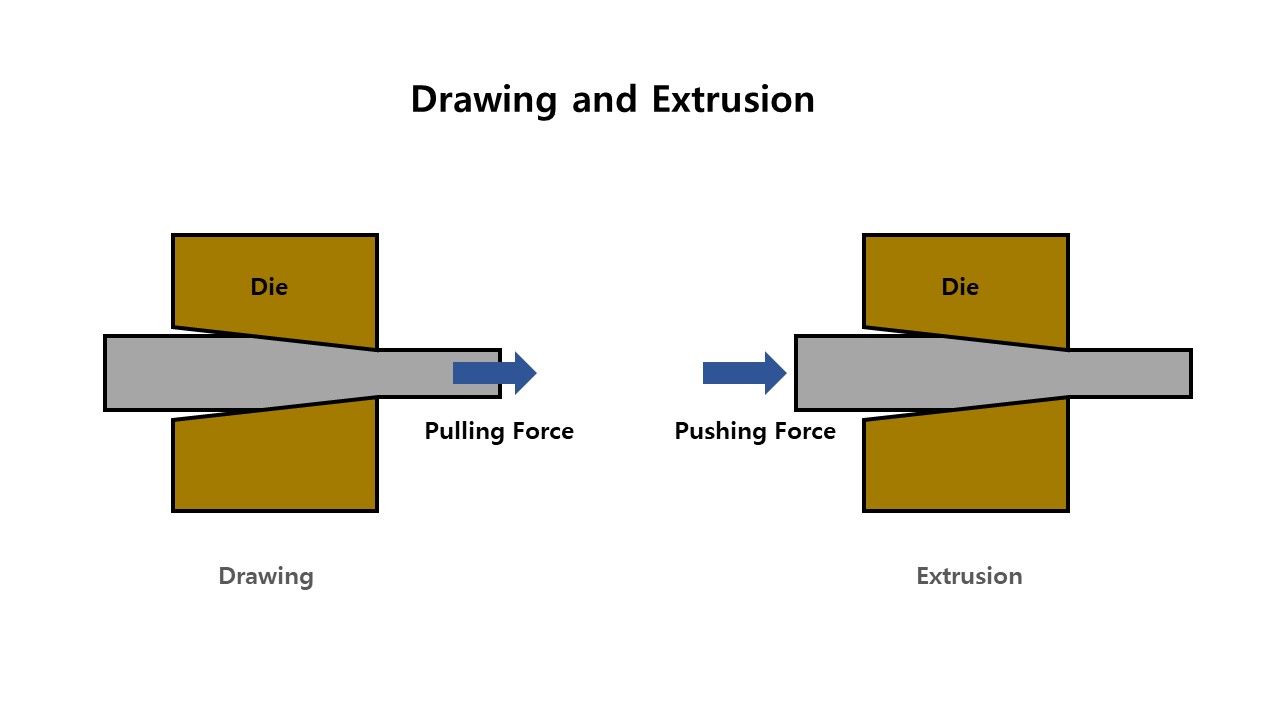

Drawing is a metalworking process used to reduce the diameter of materials, typically metals, by pulling or stretching them through dies. This elongates the material lengthwise, primarily affecting its diameter or thickness while maintaining a consistent cross-sectional shape. It is primarily used for reducing the diameter of wires, rods, or tubes while maintaining a constant cross-sectional shape.

What is Extrusion Process?

Extrusion is a manufacturing process that involves forcing a material through a die to create a continuous profile or shape with a consistent cross-sectional area. The material is pushed through the die in a lateral direction, perpendicular to the extrusion direction, causing it to adopt the shape of the die's cross-section. This method is commonly utilized to produce lengthy and uniform components with intricate cross-sectional shapes, such as pipes, tubes, and various profiles.

Drawing vs Extrusion

- Drawing is a manufacturing process that involves pulling a matrial through a die to achieve a desired shape.

Extrusion is a manufacturing process in whic a material is forced through a die to produce a desired shape.

- Drawing is typically used with mteals, whereas extrusion can be employed with both maetals and plastics.

- When considering cross-sectional shapes, drawing processes can create a variety of products with diverse

cross-sections, whereas extrusion is used to produce products with uniform cross-sectional shapes.

Drawing and extrusion are distinct manufacturing processes with different purposes and methods. Drawing is mainly used for reducing the diameter of materials while maintaining their shape, whereas extrusion is used for creating continuous shapes with a consistent cross-section. The choice between the two processes depends on the desired final product and its specific requirements.

The information provided on this webpage is intended solely for informational purposes. Steeltopia does not make any explicit or implied representations or warranties regarding the accuracy, comprehensiveness, or validity of this information.

HOME

HOME