-

About

-

Our Brand

-

Products

-

Community

Community

Blog

Blog

Process and Advantages of Continuous Casting

- Writer

- STEELTOPIA

- Date

- 23-09-20

What is Continuous Casting?

Continuous casting is a advanced casting process that was first introduced in the 1950s as an alternative method for steel production. Typically, metal rolling products are manufactured through the process of melting - casting - homogenization heating - slabbing - heating - and rolling. However, continuous casting allows for the direct casting and simultaneous rolling of billets from molten metal, thereby omitting the processes of casting, homogenization heating, and slabbing in the production process. n other words, it is a manufacturing process that shapes and solidifies metal alloys without interruption. Once secondary refining is completed, molten metal is poured into molds, rapidly cooled to ensure a uniform particle structure within the metal. The metal, after secondary refining, is then used to produce intermediate products like slabs, blooms, or billets in either the breaking down or continuous casting process. This method enhances product quality and is more cost-effective compared to other methods. The process of continuous casting is as follows:

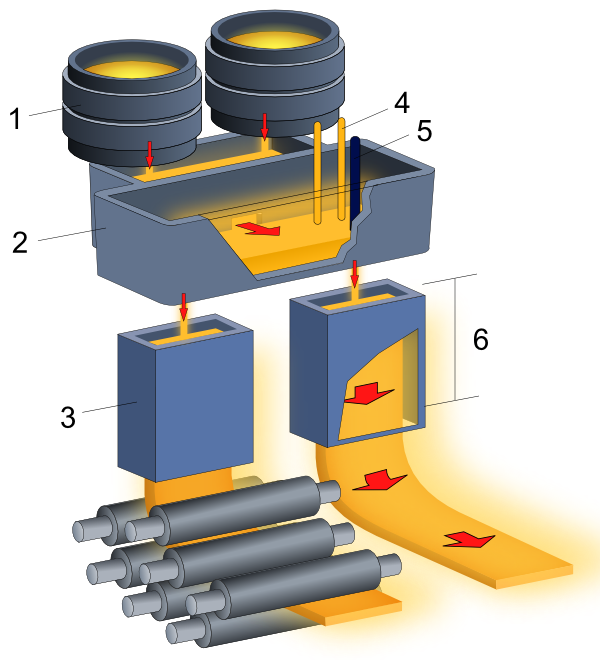

(1. Ladle. 2: Tundish. 3: Mold. 4: Plasma torch. 5: Stopper. 6: Straight zone.)

- Molten metal is poured into molds from ladles through an intermediate vessel called a tundish.

- Cooling water is applied around the mold to dissipate heat. The basic shape is formed in the mold, and partial solidification occurs.

- The semi-solidified metal, now in a solid form, is sent through pinch rolls to increase its thickness to the desired level. Cooling of the main product continues during this process.

- The fully solidified main product is then sent out through a straightening machine to meet the final specifications.

- The extracted main product is cut to the desired length using an automatic oxy-cutting machine or hydraulic shear.

Continuous casting machines are broadly categorized based on their equipment's design into vertical, vertical curved, and horizontal curved types. Additionally, the type of product being manufactured, such as slabs, blooms, or billets, is determined by the shape of the main mold. Vertical casting machines are not currently in use due to limitations in building height, with horizontal curved and vertical curved machines being the primary types employed.

Vertical curved casting machines are designed to maintain a consistent curvature in the cast product after all the metal within the main product has solidified. In contrast, horizontal curved casting machines involve a continuous change in curvature as the main product solidifies.

The significant advantage of vertical casting machines is that they allow for adequate separation of inclusions within the main product, and they exhibit minimal deformation stress on the main product apart from that. In contrast, vertical curved casting machines require the metal within the main product to remain vertical until all of it has solidified, leading to relatively higher deformation stress.

To address these issues, recent innovations involve bending the still-liquid metal while it remains un-solidified, with multiple bending points to distribute stress concentration effectively.

Advantages of Continuous Casting

Continuous casting offers the following advantages:

- It allows for the casting of metals into long tube-like shapes, which is difficult to achieve using other casting methods.

- Continuous casting requires fewer processing materials.

- Compared to other casting methods, there is less material wastage.

- Materials produced through continuous casting have a consistently dense and homogeneous structure, making them highly suitable for pressure applications.

- The surface and internal quality of the resulting billets are excellent.

- Simplification of the process can lead to cost savings in equipment.

The information provided on this webpage is intended solely for informational purposes. Steeltopia does not make any explicit or implied representations or warranties regarding the accuracy, comprehensiveness, or validity of this information.

HOME

HOME