-

About

-

Our Brand

-

Products

-

Community

Community

Blog

Blog

Stainless Steel Round Bar Application Material Specification

- Writer

- STEELTOPIA

- Date

- 24-03-22

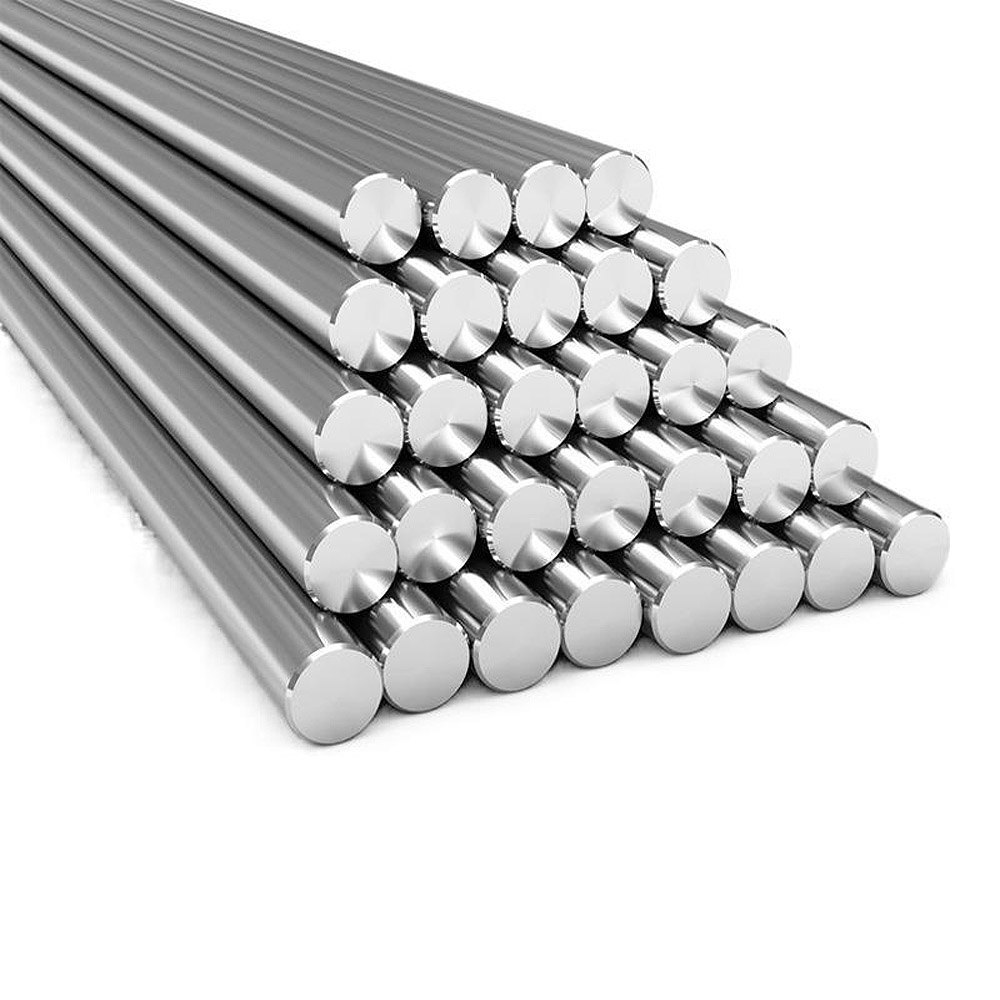

Stainless Steel Round Bar

Stainless steel round bars are cylindrical metal bars made of stainless steel, a type of steel alloy with a chromium content of at least 10.5% by mass. These round bars are used in a variety of industries due to their excellent mechanical properties and corrosion resistance.

2. Chromium: Provides corrosion resistance by forming a passive oxide layer on the surface of steel, protecting it from rust and other forms of corrosion.

3. Nickel: Enhances corrosion resistance and toughness of stainless steel.

4. Other alloying elements: Elements like molybdenum, titanium, and copper can be added to improve specific properties such as strength, machinability, and resistance to pitting corrosion.

Characteristics of stainless steel round bars:

1. Corrosion resistance: Stainless steel exhibits excellent resistance to corrosion, making it suitable for use in harsh environments such as marine, chemical, and food processing industries.

2. High strength: Depending on the grade and heat treatment, stainless steel round bars offer high tensile strength, enabling them to withstand heavy loads and stresses.

3. Heat resistance: Stainless steel maintains its mechanical properties even at high temperatures, making it suitable for applications involving elevated temperatures or thermal cycling.

Applications: Valve shafts, rotating shafts, tableware, kitchen appliances, and various mechanical parts.

Materials: 304 / 316, and many others.

Finishes:

- Polished: A smooth, reflective surface finish achieved through mechanical or electropolishing.

- Brushed: The surface is brushed with an abrasive material to achieve a satin-like finish.

- Annealing: Heat treatment finish to eliminate internal stresses and improve machinability.

(mm) | (kg) | (mm) | (kg) |

6 | 0.224 | 55 | 18.83 |

7 | 0.305 | 60 | 22.41 |

8 | 0.399 | 65 | 26.3 |

9 | 0.504 | 70 | 30.502 |

10 | 0.622 | 75 | 35.015 |

11 | 0.753 | 80 | 39.84 |

12 | 0.896 | 85 | 44.975 |

13 | 1.052 | 90 | 50.422 |

14 | 1.22 | 95 | 56.181 |

15 | 1.4 | 100 | 62.25 |

16 | 1.593 | 105 | 68.631 |

19 | 2.247 | 110 | 75.323 |

20 | 2.49 | 115 | 82.326 |

22 | 3.012 | 120 | 89.64 |

25 | 3.89 | 130 | 105.203 |

28 | 4.88 | 140 | 122.01 |

30 | 5.602 | 150 | 140.063 |

32 | 6.374 | 160 | 159.361 |

35 | 8.067 | 170 | 179.904 |

38 | 8.994 | 180 | 201.691 |

40 | 9.96 | 190 | 224.724 |

42 | 10.98 | 200 | 249.002 |

45 | 12.605 | 250 | 389.065 |

48 | 14.342 | 300 | 560.254 |

50 | 15.562 | 350 | 762.588 |

HOME

HOME