-

About

-

Our Brand

-

Products

-

Community

Community

Blog

Blog

SUS201 Chemical Composition, Mechanical Properties, Characteristics, a…

- Writer

- STEELTOPIA

- Date

- 24-11-19

SUS201 Chemical Composition, Mechanical Properties, Characteristics, and Applications

Stainless steel is an essential material used across various industries, and among its types, austenitic stainless steels are widely employed due to their excellent corrosion resistance and strength. SUS201 is a steel grade that reduces nickel content and uses manganese (Mn) as a substitute, offering both cost-effectiveness and durability.

With cost reduction becoming a critical factor in the steel industry, the demand for SUS201 has increased. This grade has potential to replace SUS304 in fields such as construction, home appliances, and automotive parts, where cost savings are important. However, SUS201 offers slightly lower corrosion resistance compared to SUS304, so understanding its properties and applying it correctly is essential.

This post will explore the chemical composition, mechanical properties, main characteristics, and practical applications of SUS201, providing insight into its potential uses in various industries.

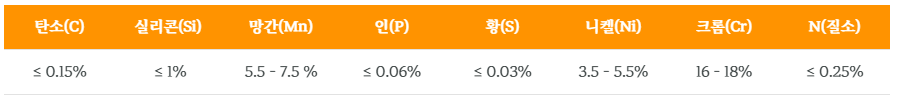

Chemical Composition (JIS G 4304 / JIS G 4305)

- Lower Nickel (Ni) Content: SUS201 has reduced nickel content compared to SUS304, while its manganese (Mn) content is higher, which helps lower production costs.

- Manganese as a Primary Alloying Element: SUS201 uses manganese as a key element, providing a balanced combination of corrosion resistance and strength.

Mechanical Properties (JIS)

- Tensile Strength (MPa): ≥ 520

- Yield Strength (MPa): ≥ 275

- Elongation (%): ≥ 40

- Area Reduction (%): ≥ 45

- Hardness: (HB) ≤ 241 / (HRB) ≤ 100 / (HV) ≤ 253

- Density: 7930 kg/m³

Key Characteristics

- Corrosion Resistance: SUS201 has relatively lower corrosion resistance compared to other grades like SUS304, so it may not be suitable for environments with high exposure to salt or acidic conditions. However, it provides adequate durability in everyday environments.

- Cost-Effectiveness: Compared to SUS304, SUS201 offers a significant cost reduction, making it ideal for projects where cost efficiency is a priority.

- Workability: While it has higher hardness than SUS304, making it more challenging to process, it can be formed into various shapes with appropriate processing techniques.

- Formability: One disadvantage of SUS201 is its higher springback tendency after forming. This means it tends to return to its original shape after bending, requiring over-bending during production to achieve the desired shape.

Primary Applications

SUS201 is a durable and cost-effective material used in various industries. Its reduced nickel content enables it to be an economical option in applications where nickel reduction is essential. Below are key areas where SUS201 is commonly used:

1. Kitchenware

- Cookware (Pots, Pans, Utensils): SUS201 provides adequate strength and durability for kitchenware such as pots, pans, and utensils.

- Sinks and Countertops: Its corrosion resistance is sufficient for everyday kitchen use, making it suitable for sinks and countertops.

2. Building Materials

- Interior Molding: SUS201 is used for interior molding and metal decorative materials, offering a sleek, shiny finish that is ideal for building interiors.

- Exterior Panels: In large-scale projects where cost-effectiveness is important, SUS201 is used for building exterior panels where high corrosion resistance is not crucial.

3.Home Appliances

- Refrigerator Doors and Microwave Interiors: SUS201 is commonly used for external parts of home appliances like refrigerator doors and microwave interiors, where it combines durability and cost-efficiency.

- Washing Machine Drums: SUS201 is also used for washing machine drums, which require high strength and longevity.

4.Automotive Parts

- Trim and Decorative Parts: SUS201 is used for exterior trim and decorative parts in vehicles, ideal for models that emphasize cost efficiency and durability.

- Exhaust System Parts: Some components of the exhaust system may also use SUS201, although in highly corrosive environments, SUS304 may be more suitable.

5.Industrial Equipment

- Low-Pressure Piping: While SUS201’s corrosion resistance is not as high, it is used for low-pressure piping and industrial tanks.

- Low-Temperature Equipment: SUS201’s strength and durability also make it suitable for low-temperature environments, including refrigeration equipment.

SUS201 provides a balance of durability and cost-effectiveness, making it ideal for applications in kitchenware, building materials, home appliances, automotive parts, and industrial equipment. It is especially useful in projects where cost-saving measures are important and can serve as a substitute for SUS304. However, it’s essential to select the right material depending on the specific corrosion resistance requirements of the environment.

At SteelTopia, we offer in-depth information on various steel materials and their applications. We hope this post helps clarify the characteristics of SUS201 and assists you in making the right material choice. For any inquiries, feel free to contact us. Thank you!

HOME

HOME